The leather horse cart in galvanized steel is the most popular solution for efficiently handling hides in leather goods and footwear factories.

This year we were able to answer a new request for a well-known leather goods maison in Paris, France. Our client had two distinct objectives for the company:

- allow the operator to safely control the quality of raw materials

- being able to handle hides without risking damage to the material and without accumulating electrostatic charges on the trolley.

All this by using a single piece of equipment: a leather horse cart made of steel.

We realised the new customised solution incorporating every request of the client: a leather trolley with a wide, smooth hump for leather goods manufacture, characterised by a compact and ergonomic design. This solution was studied for two departments in the factory: the raw materials quality control department and the finished product cutting and preparation department.

Where does the demand for the leather horse cart with a wide, smooth hump come from?

The need originated from the operator in the laboratory and then from a direct meeting with our client. Thus, after visiting the company and analysing the processes, size of materials and the various departments to equip, we studied every single detail and brought the new prototyping project to life.

What are the advantages of the leather trolley a with wide, smooth hump in leather goods sector?

The advantages of this customised leather goods trolley are:

- Ergonomic design: ensures safe loading and unloading of hides, limiting physical strain on the operator in both the quality and cutting departments. The cart is only 130 cm high.

- Wide, smooth, non-marking hump: steel curvature that safeguards leather hides.

- Extension SET: increase the useable surface area, reaching 175 cm in length.

- Three shelves: allow for more storage space for materials, with lateral access.

- Certified wheels: rubber, anti-thread and with brake (ISO 11228), allow ease of movement.

- Antistatic system: addition that allows the electrostatic charge accumulated during the phases loading and unloading the hides to be discharged (Discover more information).

Materials, dimensions and configuration of the trolley

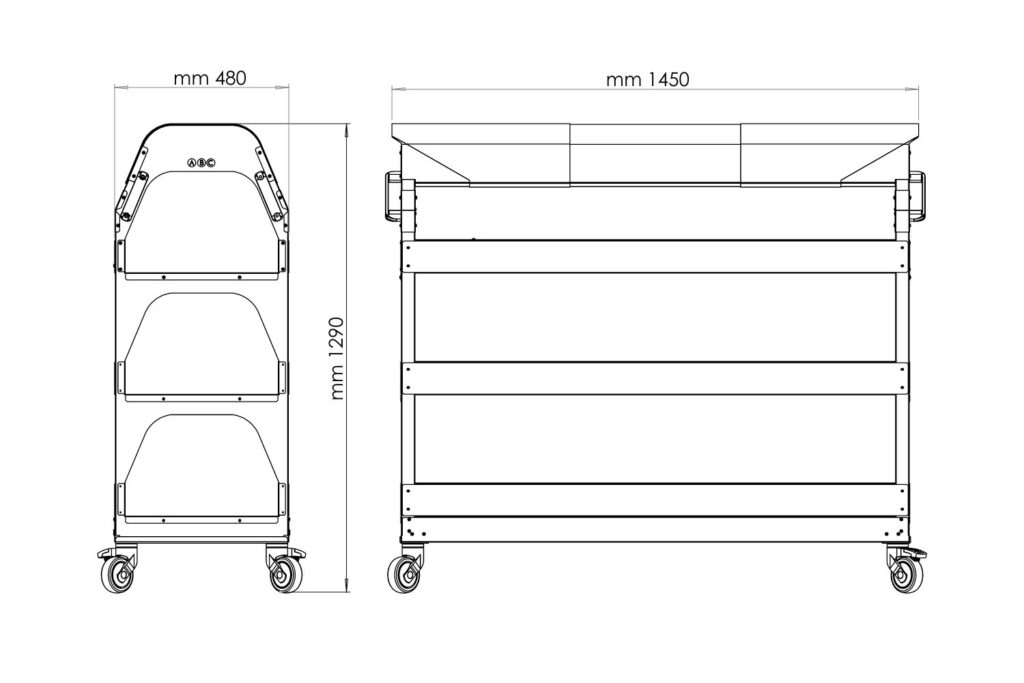

We have made this trolley in galvanised steel and what makes it stand out is its ergonomic design, studied to ensure an even more efficient and safe use. The structure is compact and robust, the horse cart measures 145 x 48 x h 130 cm and the maximum load capacity is 200 kg.

The peculiarities are:

- Upper set-up: wide, smooth hump with extension set and two bridge handles.

- Middle set-up: shelves with lateral access.

- Lower set-up: certified rubber wheels, anti-thread and antistatic system, consisting of the addition of a conductive wheel, which grounds the cart and avoids disturbing shocks to the operator.

Who inspired us to develop the leather horse cart with a wide and smooth hump?

The leather horse cart with a wide, smooth hump was created for the leather and fashion manufacturing industry and, specifically, we designed this innovative solution to ensure the safe loading and unloading of hides, limiting the physical effort of the operator in the leather goods factory.

We have developed a compact and ergonomic structure tailored to the operator:

- The 130 cm height of the trolley allows for a comfortable, agile and safe manoeuvrability for every worker.

- The wide, smooth hump guarantees, together with the extension set, a stable, secure and non-marking surface, as well as more storage space for leather hides.

- The efficient antistatic system nullifies the build-up of electrostatic charges on the trolley and thus ensures the protection of the worker.

The two main figures in the factory who use the horse cart are:

- The raw materials quality control operative, i.e. the operator who retrives and checks each new leather hide in the raw materials quality department.

- The cutting and preparation operator, also known as the ‘cutter’, for the production steps in the finished product cutting and preparation department. The horse cart works as a supplement to any type of processes: hand cutting, die cutting or with CAD and CAM digital laser cutting systems.

If you also have these needs, choose the leather horse cart with a wide, smooth hump to furnish your leather goods or footwear company.