The ABC bag trolley has been updated and modernized. It will be shown in advance at the Simac Tanning Tech 2025 fair, next September in Milan.

After visiting a French leather goods factory and talking to several customers who had already purchased the bag trolley, we made further improvements to the product.

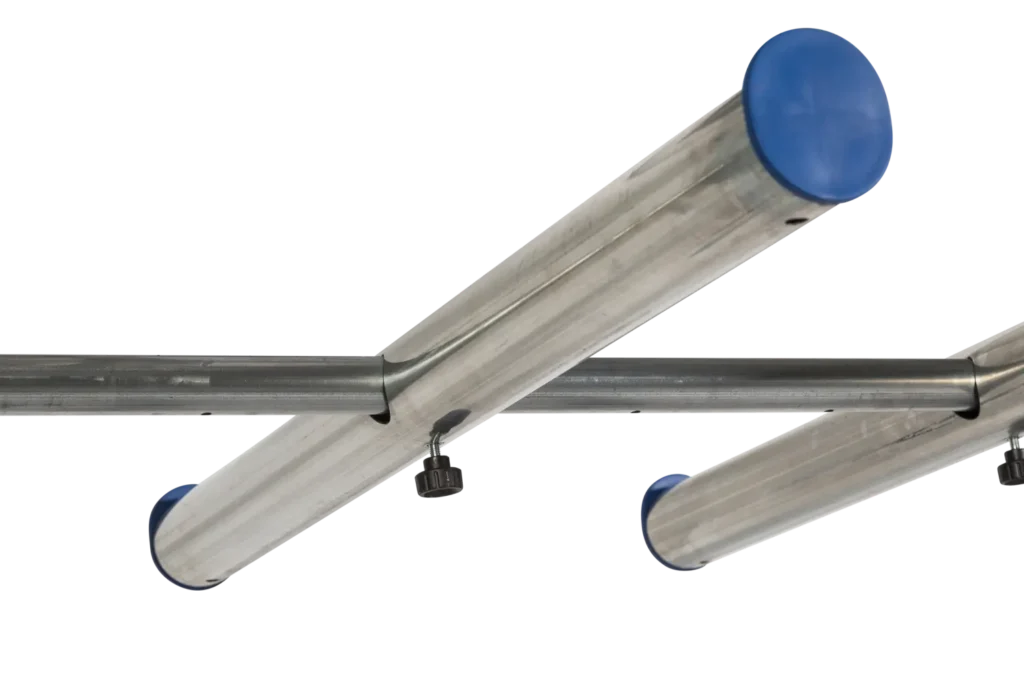

This led to a revision of the bag trolley model with the following peculiarities:

- Stackable structure to reduce bulk when the trolley is not in use

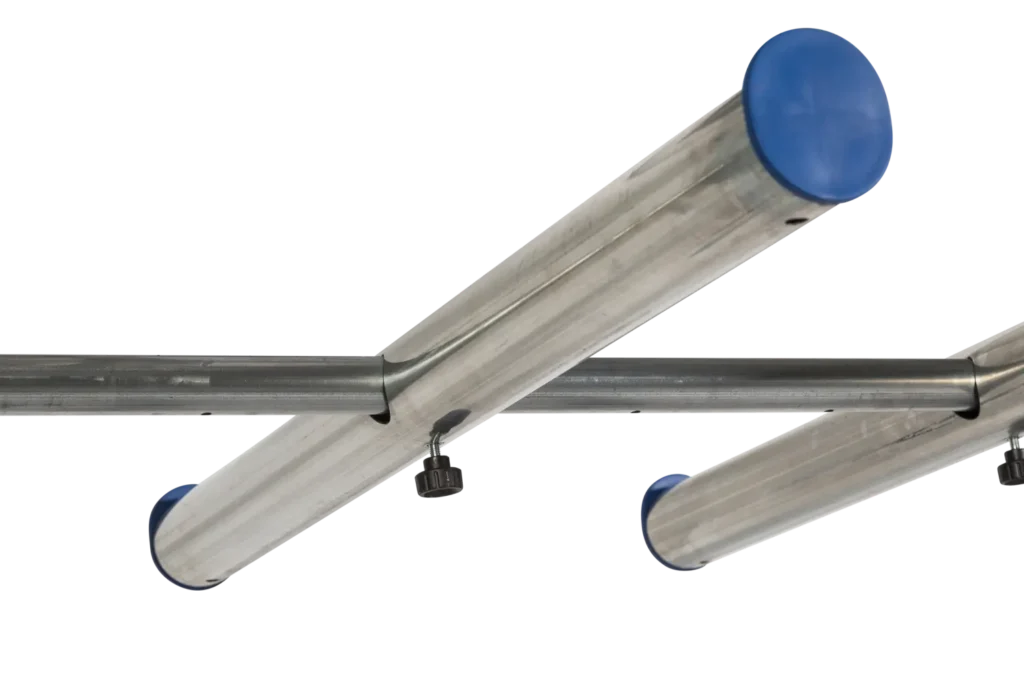

- Cylinder arms with rubber closure, to prevent damage to the bags

- Individually movable arms, to manage any type of bag

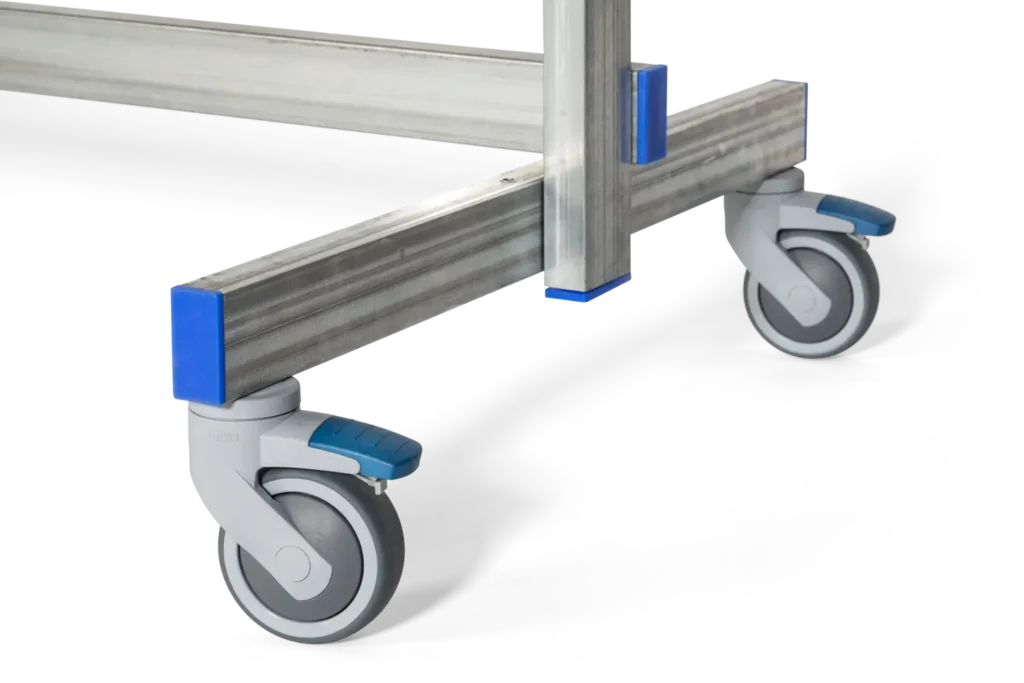

Like the previous model, the trolley is equipped with 12 arms arranged on 3 levels that can be moved and adapted to the type of product or process. The anti-thread wheels are equipped with brakes, which guarantee excellent mobility in the department.

What are the strengths of the new bag trolley?

Organizing a leather goods workshop or setting up any workstation is not so trivial at all, and developing it well can make a difference. There must be wide open space to work so that the handling of semi-finished products is easy during the various stages of production.

The new design of the bag trolley has the following strengths:

- Space optimization

The trolley is stackable so it can be easily stored with the other trolleys when not in use. Simply close the trolley arms and stack it, taking up very little space in the workshop. - Maximum customization

Each cart can be custom configured. The arms and crossbeam are movable and can be positioned wherever you prefer. Each arm can be moved independently, adapting the trolley to different bag models or production flows.

In addition, we are manufacturers and if customers need it, we make custom-made equipment, including bag trolleys.

Accessories

It is possible to complete the cart with some accessories such as:

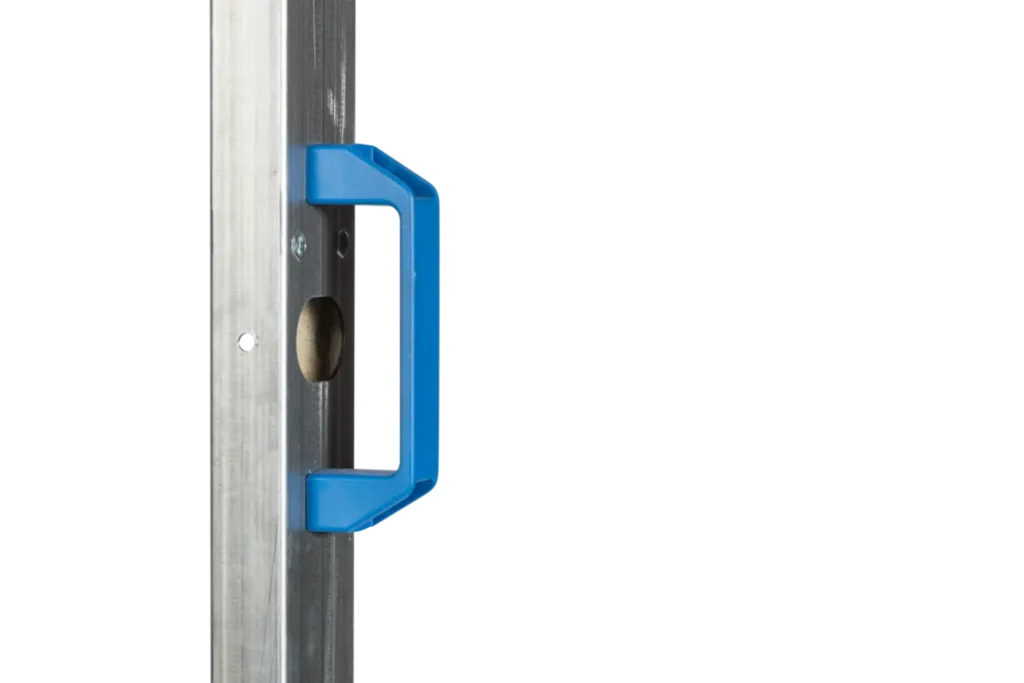

- Side handle to facilitate movement in the department. Two types available:

- Bridge handle

- Horizontal handle

- Additional arms and crossbars: for hanging and managing a larger number of bags

Painting on request

The bag trolley is supplied in resistant and durable galvanized steel but on request it can be painted, choosing a specific RAL color.

The available options are:

- Complete painting of the structure except for the crossbeams subject to wear

- Partial painting (arms only) to prevent damaging the straps of hung bags

If you work in the leather goods sector and are looking for an efficient system to organize bags during the production phases, the new ABC bag trolley is the solution designed for you. Find out in advance at Simac Tanning Tech 2025.